Fusion Fibertherm PPRC-FR Composite Pipe

Unique 3 Layer Pipe Reinforced With Glass Fiber, Made From the Next Generation PPRC-FR Composite, An Unrivalled Product

Fusion Industries Limited is proud to introduce an innovative product fusion PPRC-FR composite pipes for compressed air. Modern process equipment, pneumatic controls, and instrumentation, however, demand a supply of clean, uncontaminated air and maintenance of the cleanliness of this air, from source right up to the point of use is obviously essential.

The system is designed specifically for the conveyance of compressed air and with its new and unrivalled properties becomes the ideal choice for critical applications.

Fusion Fiber Therm composite pipe for AIR-LINE PIPES KEEPS AIR CLEAN-RIGHT UP TO THE POINT OF USE.

The middle layer Fiber Glass reinforced within the two layers of PPRC acts as an agent to reduce extension capability and produce durability to high pressure at high temperature.

In ordinary PPR pipe inner dia is smaller & air flow is less but in Fusion Fiber Therm PPRC-FR Composite Pipe Air flow will be 25% higher.

COMPARISON OF FUSION FIBERTHERM COMPOSITE PIPES & ALLUMINIUM PIPES

| FIBER THERM COMPOSITE PIPE | ALLUMINIUM PIPE | |

| JOINING SYSTEM RELATED TO LEAKAGES | Socket Fusion Joining System Assuring 0% Leakage | 100% chances of leakages due to push fit joint depending on O-rings |

| RA VALUE RELATED TO FRICTION LOSS | 0.1 Micro RA Value insures negligible friction loss and assures good amount of energy saving | 0.7 micron RA value leads to higher friction loss which creates high energy consumption |

| C VALUE RELATED TO HIGH FLOW | 150oC Value gives higher and smoother fiber reducing the energy consumption | 130oC Value depending on O-rings consumes more energy |

| PRESSURE HOLDING TEST | Glass Fiber Reinforcement composition with Polypropylene is successful in pressure holding test | Push Fit joints depending on O-rings fails in pressure holding test |

| THERMAL CONDUCTIVITY RELATED TO MOISTURE | Moisture Free Fusion brand pipe having 0.013 Btu/hr F thermal conductivity assures moisture free and 100% Non-corrosive pipeline | Higher thermal conductivity 27.09 Btu/hr F creates moisture in the pipeline ultimately leading to corrosion |

| MAINTENANCE RELATED TO CORROSION | NIL maintenance owing to 100% leak proof element and NIL corrosion | Very high maintenance due to push fit joints |

| LIFE EXPECTANCY RELATED TO CORROSION | 25 year of life without Sagging and with nice aesthetic view | Maximum 5 years of life with maintenance due to leakages and higher thermal conductivity |

| ENERGY SAVING | Energy Saving due to 0% leakages | Higher Energy consumption Due to Friction Loss & leakages |

Fusion FIBERTHERM Composite Green pipes for industry

Fusion fibertherm pipe

The innovative all-rounder product which revolutionized the plastic industry, made a name for itself within a very short time that stands highest quality and outstanding ecological properties.

Fusion fibertherm is multiplayer with fiber reinforced and UV resistant makes its mechanically stabilized through a fibertherm mix integrated in the middle layer and outer layer is resistant against UV sun rays and inner layer is ppr food grade material

Advantages over ordinary PPR & other polymer pipes

- 4x lower linear thermal expansion

- Higher pressure bearing capacity, up to 25% than normal PPRC pipes

- Higher flow rate 25% (Bigger ID)

- Energy saving up to 25%

- Fibertherm pipes reduce passive heat loss by around 20% for non-insulated pipe

Applications:

- Compressed AirLine

- Portable water Hot and Cold

- Cooling and Chilled Water

- HVAC & Air Conditioning

- Chemical & Acid

- Hydraulic Oil (Pressure 20kgf)

- Geo thermal application

- Recycle water

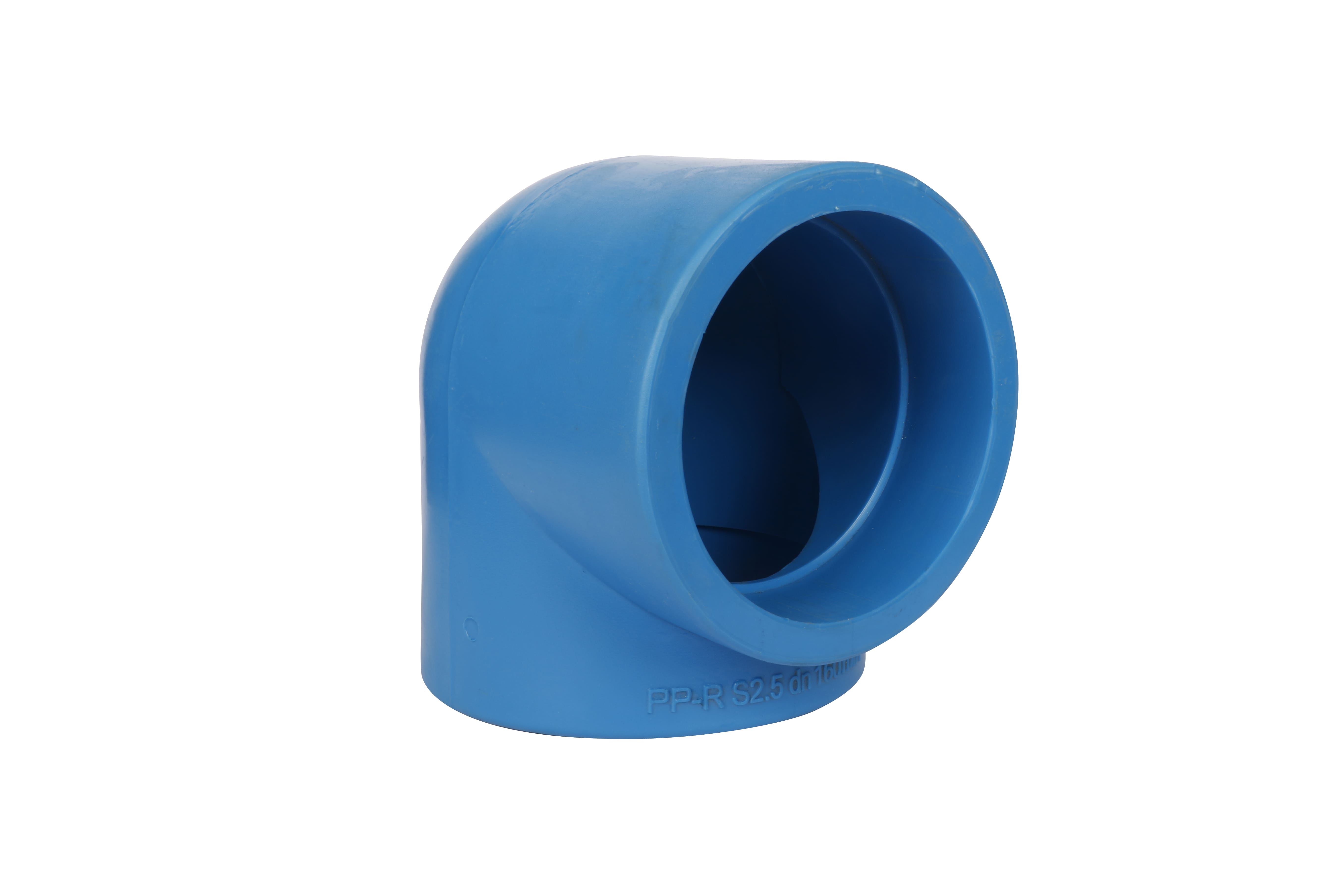

A FEW FIBERTHERM FITTINGS

FIBERTHERM BLUE ELBOW

FIBERTHERM BLUE TEE

FIBERTHERM BRASS MALE MTA

FIBERTHERM GREEN ELBOW FT

FIBERTHERM GREEN ELBOW

FIBERTHERM BRASS FTA

FIBERTHERM BRASS MALE TEE

FIBERTHERM BRASS MTA

FIBERTHERM COUPLER BLACK

FIBERTHERM ELBOW BLACK

FIBERTHERM FLANGE SILIPON

FIBERTHERM REDUCING TEE