Fusion P.T.F.E. THREAD SEAL TAPES

Fusion Leakage-Free Heavy-Duty Teflon Tapes

Fusion PTFE Thread Seal Tape is a high purity, high-density tape manufactured using premium grade virgin PTFE (polytetrafluoroethylene). Fusion PTFE Tapes are resistant to a broad range of corrosive chemicals, gases, acids, and liquids.

PTFE (Teflon) Thread Seal Tape is made from highly versatile lubricating material used as a sealant in plumbing for pipes and ductwork. This lubricating property of these tapes helps for the deep and prolonged setting of the thread and helps in preventing thread seizures after being unscrewed.

It is mainly used in pipe and fitting applications and is also known as a plumber's Seal Tape. Like other types of professional adhesive tapes, it is also sold pre-cut to a range of specified widths on small rolls or spools.

The main characteristics of PTFE include hydrophobic and extremely low friction. This makes it highly useful for many different pipe & fitting and plumbing applications.

Features

- Lower porosity due to high density.

- Compatible with broad range of gases, and liquids across various piping materials.

- Does not harden/ crack on joints.

- Easily removable for maintenance.

- Effective across wide range of temperatures and pressures.

- Prevents electrolytic corrosion of threaded joints.

- Zero curing time, unlimited shelf life, non-flammable.

SALIENT FEATURES

Grips Well

Durable

Easy To Use

Leak Proof

Flexible

Low Cost

APPLICATIONS

Fusion PTFE Thread Sealant Tapes are used for various media applications ranging from corrosive chemicals, water, gas, lubricants, oil solvents.

Main Technical Indexes

- Heat Resistance: +370° C

- Cold Resistance: -190° C

- High Pressure Resistance: 150-220 Kg/cm2

- Tensile Strength: 8 N/mm2

- Percentage Elongation: >> 75 %

| WIDTH | THICKNESS | LENGTH |

| 12 mm | 0.1 mm | 10 Mtr. |

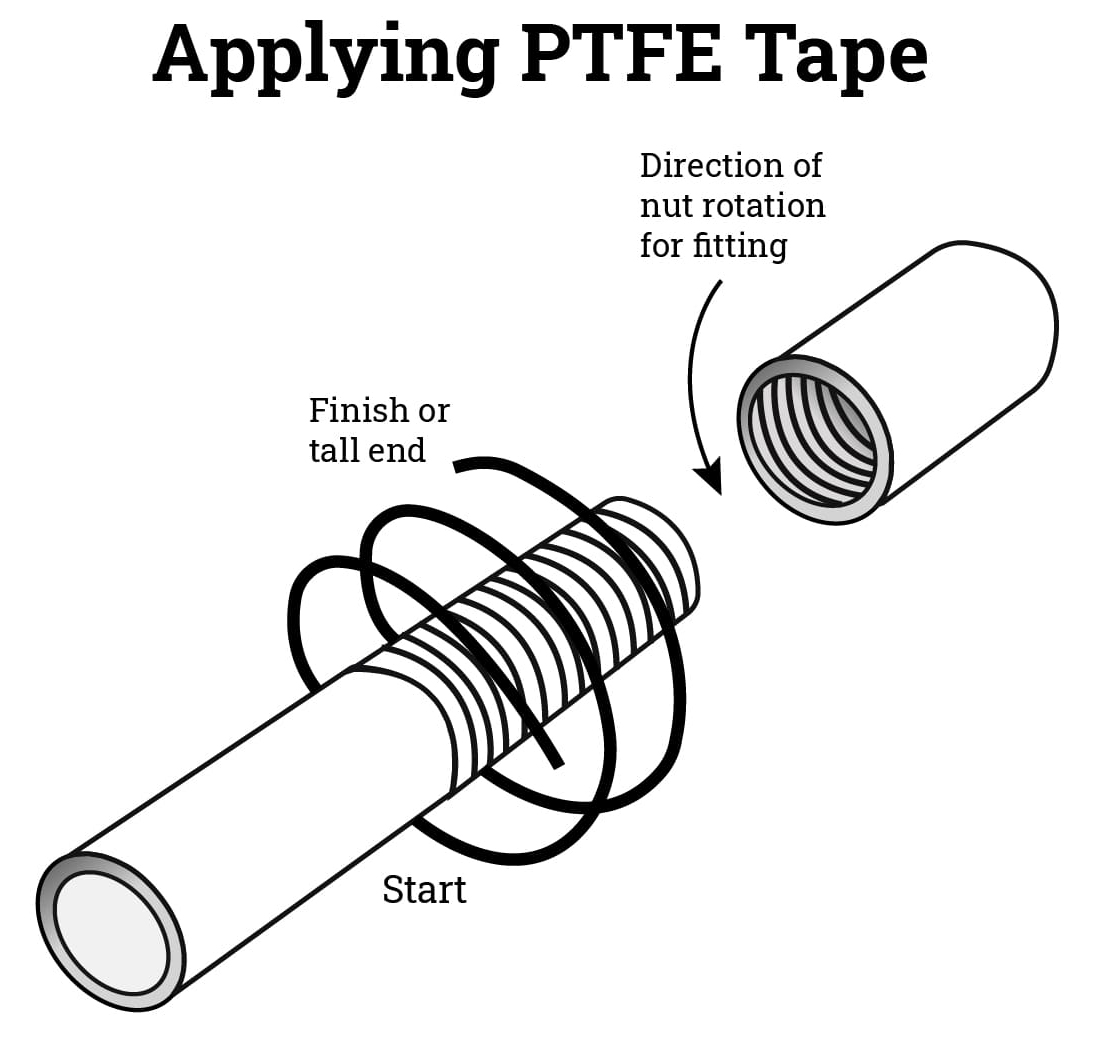

Applying PTFE Tape

The correct way to apply the tape is to follow the direction of the thread as if you were tightening up the nut. 99.9% of the time, nuts tighten up clockwise, so this is the way you should also apply the PTFE tape.

For the sake of proving the point, you could wind the tape anti-clockwise onto the thread. If you are right-handed, you will probably find it quite awkward to do, but more importantly, when you try and screw the nut on, you'll find that the PTFE will start to come off. This renders the PTFE tape completely useless and highlights exactly why you should wrap it around the thread in a clockwise motion.

When applying the tape clockwise, it's recommended that you wrap it around the thread three or four times. This is thick enough to prevent leaks, but not too thick that you can't get the nut on. When putting the nut on over clockwise-wound tape, you'll see if fits over easily and the tape does not start to come off, in contrast to when it was wound anti-clockwise.